We dedicated over 12 years into the fasteners business, by decades of experiance, we are responsible to provide the most qualified fastener products for our valuable customers.

To assure the quality utmostly, to reduce the worryabouts from the customers maximumly, to prove HAIYAN BOLT is a trustable, reliable, processional manufacturer.

All the fasteners made by HB, for those high tensile strength fasteners, especially over and including 8.8 grade or ASME GR5, will be sent to third lab for the physical properties inspection and issue the report.

We believe in our products can bring the reputation to our customer, and winning the market meanwhile.

For now, allow us to present the third party indepentent labs for your reference (Zhejiang National Testing Technology Co., Ltd. / Shanghai Juncong Testing Technology Co., Ltd.) which have been providing fastener inspection service with HB over years, they are all CNAS, CMA, ILAC-MRA, CAL certified and approved.

Zhejiang National Inspection and Testing Technology Co., Ltd. is the first national third-party testing organization to explore the reform and establishment of the national quality inspection system on the basis of the national standard parts product quality supervision and Testing Center (since 2001).

The company has passed CMA, CAL, CNAS, DILAC, NADCAP. Obtain the qualification of steel structure testing in construction industry. At present, the laboratory can carry out the testing of standard parts series products, metal materials, mechanical parts, welding materials, bearings, and other non-metallic materials such as composite materials, rubber, plastic, paint, etc.

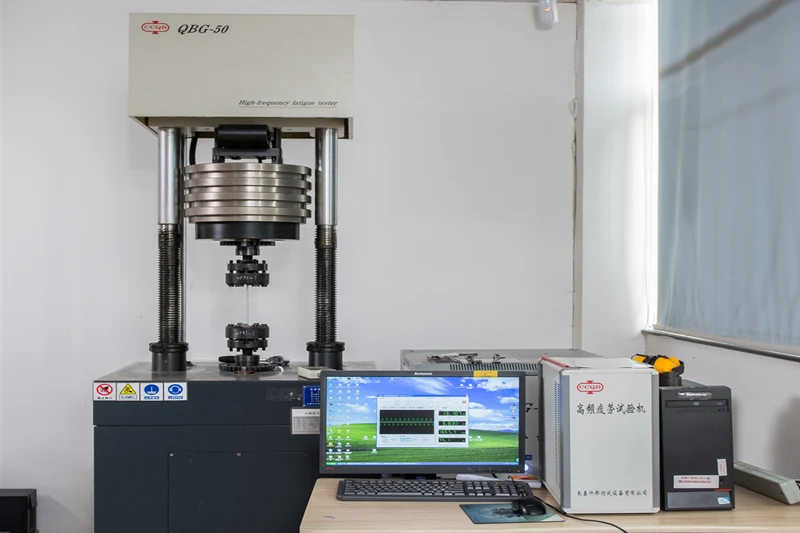

At present, the laboratory covers an area of 10000 square meters, equipped with more than 350 sets of advanced equipment, such as American direct reading spectrometer, Zeiss microscope, scanning electron microscope, high temperature tensile testing machine, high temperature drying testing machine, high frequency and low frequency fatigue testing machine, phased array, TOFD and so on. The test results are accurate and reliable.

Detection of harmful substances: analysis of harmful trace elements in product sample components, the analysis report

Testing equipment: direct reading spectrometer, inductively coupled plasma emission spectrometer

Hydrogen embrittlement performance: in the process of metal solidification, into which hydrogen can not be timely released, will spread to the nearby defects in metals, to room temperature atomic hydrogen defect in the synthesis and accumulation of molecular hydrogen, thus resulting in the great pressure, the metal crack; under stress, in solid solution hydrogen in metals may also cause hydrogen embrittlement, metal lattice in the wrong row atoms, hydrogen gathered near the dislocation, metal materials under the action of external force, the non-uniform stress distribution inside the material, the material shape rapidly transition region or the occurrence of stress concentration in the defects and micro cracks, due to hydrogen in the area of stress concentration and enrichment of the region to promote plastic deformation, resulting in the crack initiation and propagation; in the crystal has many micro cracks, crack aggregation hydrogen to adsorption on crack surface, the surface can be reduced, thus the crack propagation easier.

Fatigue reliability: fatigue test is a reliability test, the specimen or analog parts in various environments, subjected to alternating load and determination of its fatigue performance criteria, test and Study on the fracture process. The center can serve as a reliable performance of professional bodies can complete fatigue performance test of various products in accordance with the ISO, ASTM, DIN, GB, HB and other standards.

Testing equipment: fatigue test machine, constant temperature and humidity test machine, etc.

Defect detection: using machine vision detection technology of advanced detection of surface defects, defects on the surface of the spots, scratches, pits, chromatic aberration, defect detection.

Testing equipment: ultrasonic detector, cover thickness tester, magnetic powder flaw detection machine etc.

Our laboratory can analyze the compositions of ferrous metal, non-ferrous metals and their alloys, Our laboratory also can test heavy metal, gas and elements according to ROHS.

Carbon analysis

Silicon analysis

Manganese analysis

Phosphorus analysis

Sulfur analysis

Chromium analysis

Nickel analysis

Molybdenum analysis

Vanadium analysis

Copper analysis

Titanium analysis

Cobalt analysis

Tungsten analysis

Aluminum analysis

Boron analysis

Niobium analysis

Salt spray test

Optical Emission Spectroscopy Tester, ICP Spectroscopy Tester, Hydrogen Analyzer, Oxygen Nitrogen Analyzer, Carbon Sulfur Analyzer, Spectrophotometer.

Appearance dimensions: Screw gauge, roughness, all kinds of length dimensions

Short Term Mechanics: Brinell Hardness, Rockwell Hardness, Vickers Hardness, Re-tempering Test, Normal Temperature and High Temperature Tensile Test, Static Load Anchoring, Proof Load, all kinds of Prevailing Torques, Locking Performance, Torque Coefficient, Fastening Axial Force, Friction Coefficient, Anti Sliding Coefficient, Drive Test, Washer Spring, Toughness, Hydrogen Embrittlement Testing, Flattening, Rubber Bearing, Flaring, Widening Test on nuts, Bending, Single-sided and Double-sided shearing test, Pendulum Impact and etc.

Long Term Mechanics: Stress Relaxation, High Temperature Creep, Stress Rupture Test, Transverse Vibration, and Fatigue Test.

Testing Equipment (small Exhibit attached): Roughness Tester; Profilometer; Electro-hydraulic Servo Universal Testing machine (1---400T); Stress Relaxation Testing Machine; Static Load Anchoring Testing Machine; Microcomputer Servo Pressure Shearing Testing Machine; Torque Coefficient Tester; Vivtorinox Hardness Tester; Transverse Vibration Testing Machine, Fatigue Testing Machine, and Stress Rupture Testing Machine

Crack analysis: According to the common crack, crack, crack, crack, circumferential annular radial crack, arc crack, the observation and the analysis of the crack shape and grinding by high precision electronic microscope, find out the cause of the crack;

Fracture analysis: Fatigue source zone, analysis of fracture propagation region parts, transient fault zone, load type and size to find fault, find out the exact cause of fracture, in order to prevent the fracture failure again to take measures to provide the basis for;

Corrosion analysis: Mainly for their parts in the use process, due to corrosion, so as not to the design requirements of function, or corrosion fracture,or not the safe and reliable operation and service and failure, by looking for the cause of failure, to avoid repeated failure accidents like corrosion; eliminate hidden dangers, to overcome the weak link in production, improve the manufacturing quality of equipment, guarantee the safe operation and prolong the service life of the equipment; improved structure design of equipmentand improve the performance of the device, ensure the advanced equipment; to formulate operation process and operationreasonable rules of discovery and development of anti corrosion; the new theory, new materials and new technology for the production of services;

Analysis of unqualified process evaluation: The submission of the unqualified samples detection parameters, further analysis combined with the production process of products, find the links exist production, processing products, and provide a reliable basis for the enterprises to improve product quality, material etc.;

Fracture analysis: Fracture always occurs in the metal microstructure of the weakest, recording a lot of valuable information about the whole process of fracture. And classification, the conclusion through the macroscopic morphology on the fracture surface andmicrostructure characteristics of the close relationship between the direct observation and analysis as well as with theenvironment and time factor.

The precision measurement businesses of our laboratory can measure the precise dimensions, shape and position tolerance, thread angle, major diameters, pitch diameters, minor diameters of the machinery parts, thread fasteners and special fastener products.

Dimensions Measure

From and Position Tolerance Measure

Thread Angle

Major Diameters, Pitch Diameters, Minor Diameters

MAHR profiler

Cylindricity Measuring Instrument

Thread precision measurement system

Metallographic Analysis Dept. mainly carries out the metallographic testing analysis of the fasteners and other metal products at present.

Microstructure

Macrostructure

Grain size

Non metallic inclusions

Decarburization

Carburizing

Nitriding

Intergranular corrosion

Micro hardness

Coating testing

Ferrite content testing

Magnetic testing

Hitachi scanning electron microscope (including energy spectrometer)

Zeiss microscope (Research Level)

High and low temperature environmental testing chamber

Stress corrosion testing machine

Program controlled heat treatment furnace

Meanwhile, HB is 7X24 standby for customer's testing requirement. Even for those which not made by HB, we are open to provide the third party test service. Saving customers' value time, we can make it happen in China...